by Loïc

Where we look for raw materials

On the page "Touring the system !" we used a glass coil found totally by chance in an old cardboard box… So as to allow as many people as possible to see "really" what happens in a pop-pop, I tried to build a complete coil from glass pipes. On the page "Touring the system !" we used a glass coil found totally by chance in an old cardboard box… So as to allow as many people as possible to see "really" what happens in a pop-pop, I tried to build a complete coil from glass pipes.

The pipe used here was ordered to a company who use to supply lab stuff for schools, but it also sells to any people. I ordered 10 pipes of borosilicated glass (glass more resistant to thermal chocks than regular glass, similar to Pyrex), of internal diameter 4 mm, external diameter 6 mm (4x6), 500 mm long. The pipes that have been delivered (and got there fine!...) were not engraved with the borosilicated indication… and, as the same pipes exist in regular glass, I doubt I got the requested ones (See further). The pipe used here was ordered to a company who use to supply lab stuff for schools, but it also sells to any people. I ordered 10 pipes of borosilicated glass (glass more resistant to thermal chocks than regular glass, similar to Pyrex), of internal diameter 4 mm, external diameter 6 mm (4x6), 500 mm long. The pipes that have been delivered (and got there fine!...) were not engraved with the borosilicated indication… and, as the same pipes exist in regular glass, I doubt I got the requested ones (See further).

Where we start

What follows is around a steel bar squeezed in a vice, and a welding torch (here a butane one) in hand. The wider the flame, the easier the job... What follows is around a steel bar squeezed in a vice, and a welding torch (here a butane one) in hand. The wider the flame, the easier the job...

To shape the pipe, it must be heated until it accepts to be bent by hand… If too much heated, it bents by its own weight and shaping becomes more delicate. Then, it suffices (Yes! Yes!) to rolling it progressively around the steel bar (heated before). Four hands are not too many (Thank you Yann!) to do the job… To shape the pipe, it must be heated until it accepts to be bent by hand… If too much heated, it bents by its own weight and shaping becomes more delicate. Then, it suffices (Yes! Yes!) to rolling it progressively around the steel bar (heated before). Four hands are not too many (Thank you Yann!) to do the job…

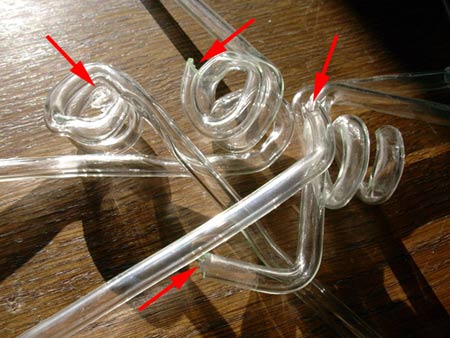

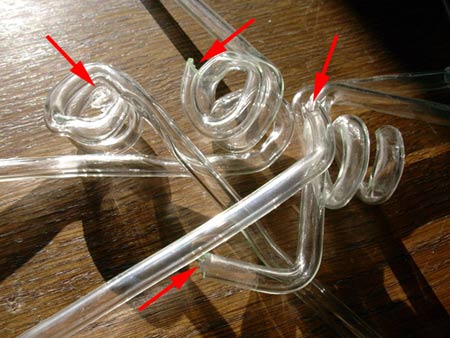

Useless to say that the first attempts lead to twisted glass, without definite shape!... One of the problems is the sticking of a spiral on the next one. So, they have to be spaced, and could be "piled up" later… Don't forget that hot glass is as soft as caramel!... After learning, 5 coils, each with 2.5 spirals, were made. The shape is not yet perfect, but… well… we will say that it is OK for a first attempt! Useless to say that the first attempts lead to twisted glass, without definite shape!... One of the problems is the sticking of a spiral on the next one. So, they have to be spaced, and could be "piled up" later… Don't forget that hot glass is as soft as caramel!... After learning, 5 coils, each with 2.5 spirals, were made. The shape is not yet perfect, but… well… we will say that it is OK for a first attempt!

Where we try to make glass boilers work !

After three cutter stabs, the float is ready… Add two pliers strokes to do the burner (cotton + alcohol) and a match is struck for the first test. After three cutter stabs, the float is ready… Add two pliers strokes to do the burner (cotton + alcohol) and a match is struck for the first test.

It warms up… the coil empties as usual (see here the detailed working)... Here it is. The coil is empty… the water starts to climb up… climbs down… and suddenly up !! Tchac !! It warms up… the coil empties as usual (see here the detailed working)... Here it is. The coil is empty… the water starts to climb up… climbs down… and suddenly up !! Tchac !!

The coil has just broken due to the thermal chock when the water climbed up! It could have been expected… but… The coil has just broken due to the thermal chock when the water climbed up! It could have been expected… but…

Hey! What if we tried to release the strains by a sort of annealing?? Hey! What if we tried to release the strains by a sort of annealing??

Who takes no risk gets nothing… A ceramic burner originally intended to be used for central heating is requested to help. Who takes no risk gets nothing… A ceramic burner originally intended to be used for central heating is requested to help.

Two hours "on the fire", as can be seen on the picture… a very little deformation of the parts is visible… obviously there are (there were?) some strains inside the glass. Two hours "on the fire", as can be seen on the picture… a very little deformation of the parts is visible… obviously there are (there were?) some strains inside the glass.

A slow cooling down and we jump to the second test… Well, bah… it will be necessary to improve our knowledge about glass… indeed the tests n°2 to 4 involved the coil braking when the water climbed up, as for the first test… A slow cooling down and we jump to the second test… Well, bah… it will be necessary to improve our knowledge about glass… indeed the tests n°2 to 4 involved the coil braking when the water climbed up, as for the first test…

Where temporarily we conclude

Four main points : Four main points :

- It is possible to build coils that look to something

- The annealing technique should be improved...

- The pipes I received had no labelling to indicate that they were made of borosilicated glass… I doubt about the quality of what was delivered… might be ordinary glass… (very sensitive to thermal chocks). July 2006 : now I know that the borosilicated glass has a blue-green tint at breaking point. The pipes used have indeed this break color, thus it is most likely borosilicated glass (Pyrex type glass)...

- We should take some time to be in touch with glass specialists to get their advices…

While waiting for this, nothing prevents you to run your own tests. Besides, I will be pleased to get some news from you on this topic! While waiting for this, nothing prevents you to run your own tests. Besides, I will be pleased to get some news from you on this topic!

We will come back on this later, because I intend to continue the tests! We will come back on this later, because I intend to continue the tests!

« Back to "Pop-pop"

|